Welcome to AADHI Tape Solutions, a company established in 2020 that specializes in the manufacturing and supplying of high-quality adhesive tapes and primers.

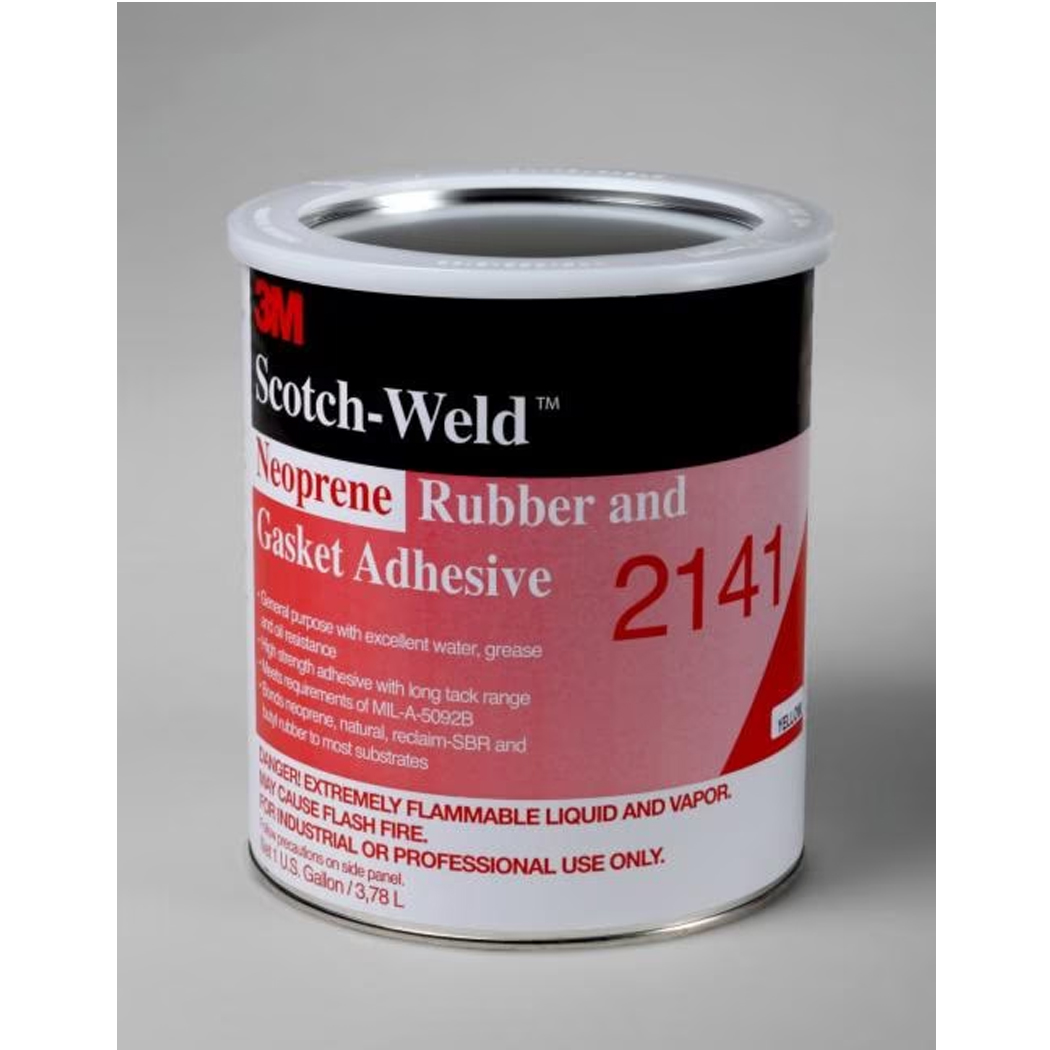

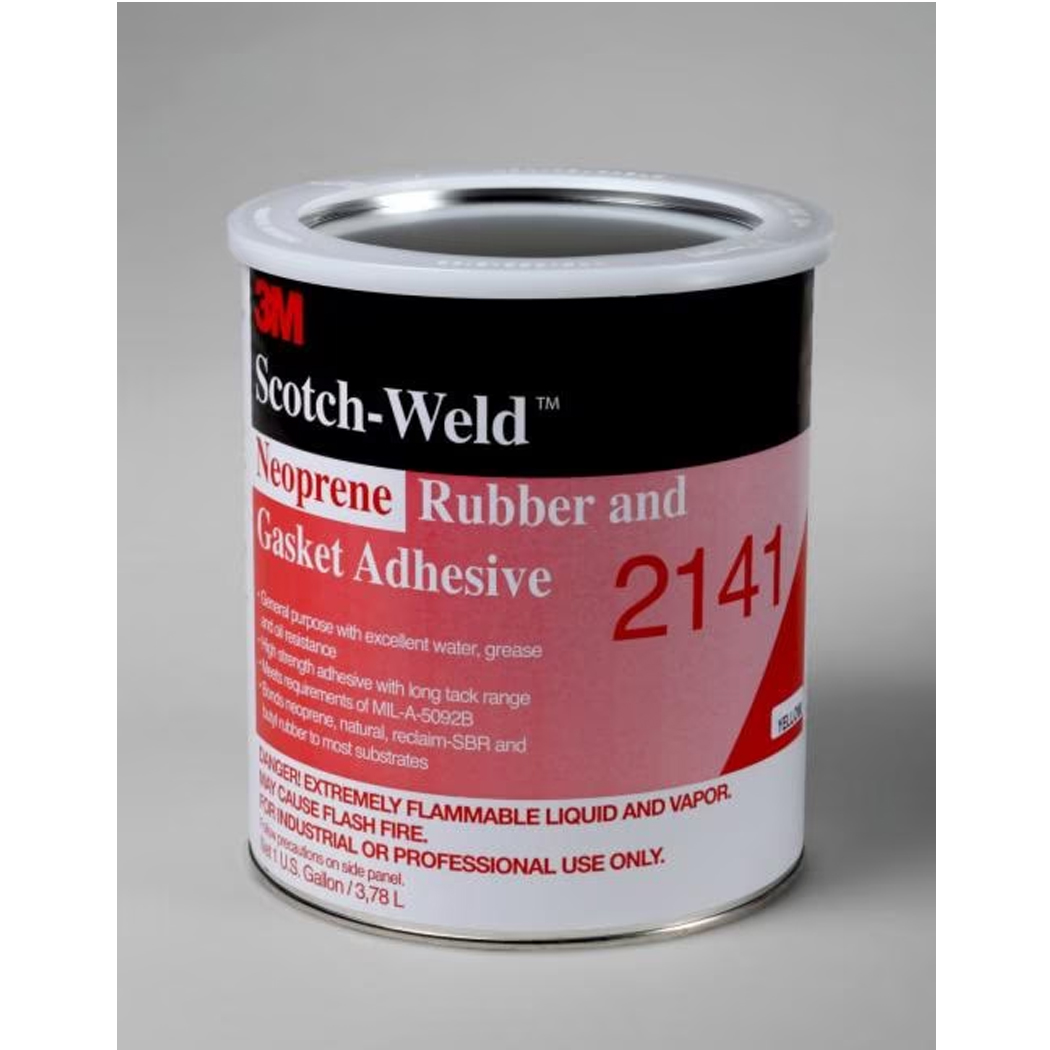

3M™ Neoprene High Performance Rubber and Gasket Adhesive 2141

Description

Highlights

- High performance adhesive forms strong bonds in as little as 15 minutes

- Adheres to neoprene, SBR, butyl, leather, vinyl and various rubbers

- Excellent fuel and oil resistance

- Heat and chemical resistant allows for use in unique and harsh environments

- Offers long tack range for precise placement

- Light yellow in appearance

3M™ Neoprene High Performance Rubber and Gasket Adhesive 2141 is an all-around reliable synthetic rubber adhesive best used in general industrial applications. It is used to bond materials to a variety of substrates including most metal, baked enamel, wood, plastics, neoprene, and various rubbers. It is a high strength adhesive with a light yellow appearance.

A Fast Strengthening Bond With its high strength and long initial tack range, our 3M™ Neoprene High Performance Rubber and Gasket Adhesive 2141 is an ideal choice for general rubber and gasket bonding purposes. Its bond forms strongly in fifteen minutes, and yet it provides ample time for the user to position parts correctly prior to the bond’s full setting. It brushes on easily, but can also be sprayed-on for quick, repeated, and precise application. This solvent-type synthetic rubber adhesive features excellent resistance to water, oil and grease in a variety of unique and harsh industrial environments. It has proven to successfully bond neoprene, natural, reclaim SB-R and butyl rubber to most substrates. For best results, the temperature of the adhesive and the surfaces being bonded should be at least 65°F (18°C). Recommended Applications Bonding rubber and gasketing materials Patching materials exposed to the outdoors Bonding fabric and leather to metal, wood and many plastic surfaces Bonds Neoprene, Natural, Reclaim SB-R and Butyl Rubber We designed 3M™ Neoprene High Performance Rubber and Gasket Adhesive 2141 to bond to many materials: metals, wood, leather, many rigid and flexible foams, various plastics, paper, cardboard, fibrous glass, hardboard, glass, ceramic, baked enamel, reclaim, SRB and butyl rubber. This adhesive makes small work of big jobs in the workplace. Applying Your Adhesive Whether it is being sprayed, brushed or rolled on, the application of your 3M™ adhesive is a straightforward process. Start by carefully applying your adhesive to your surface until you’ve formed a uniform coat. Using an overlapping pattern, the application of one coat should prove sufficient for most surfaces. Some substrates, including porous materials, may require an additional coat. In order to apply additional adhesive, simply wait until the existing adhesive becomes dry to the touch, and then proceed with the application of the additional coat. Click here for more information on 3M Industrial Adhesives

Additional information

| Application Method | Flow, Brush |

|---|---|

| Application Temperature From (Celsius) | -30 ℃ |

| Application Temperature To (Celsius) | 80 ℃ |

| Brands | 3M™ |

| Container Size (Metric) | 3.8 Litre, 18.93 Litre, 1 Litre |

| Flame Retardant | Flammable |

| Form | Liquid |

| Heat Resistance | <170 Degree Fahrenheit |

| Heat Resistance (Celsius) | <77 °C |

| Industries | General Industrial |

| Open Time | Up to 15 min |

| Physical Form | Liquid |

| Product Form | Quart |

| Product Type | Accessory |

| Solids Weight Percent (Approximate) | 30 % |

| State Restrictions | NJ, RI, NY, PA, VI, MD, ME, MI, OH, CT, DC, IL, CA, DE, MA |

| Surface Type | Plastic, Rubber, Fabric, Wood |

| Units per Case | 1.0,12.0,4.0 |