Welcome to AADHI Tape Solutions, a company established in 2020 that specializes in the manufacturing and supplying of high-quality adhesive tapes and primers.

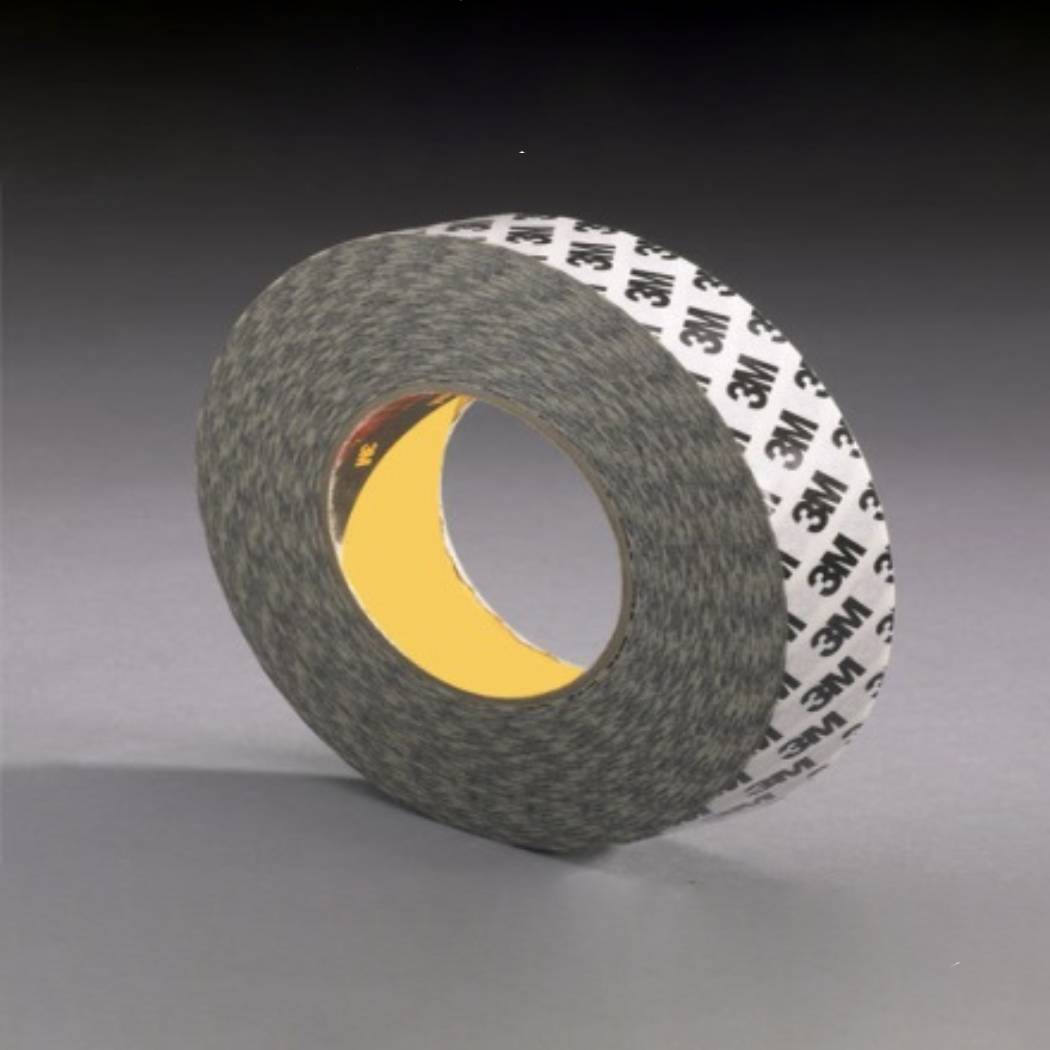

3M™ Adhesive Transfer Tape 950EK

Description

Highlights

- EK liner (Extensible Polycoated Kraft) enhances tensile strength and tear resistance

- Acrylic adhesive 300 offers high adhesion rate to HSE and LSE materials

- Useful for many applications, from splicing to laminating

- Superior UV and chemical resistance

- Exceptional tack and shear strength

3M™ Adhesive Transfer Tape 950EK is part of the 3M™ High Strength Acrylic Adhesive 300 family. This pressure-sensitive, medium-firm acrylic adhesive features very high initial peel and good shear holding power. Plus, it adheres well to a variety of surfaces, including HSE and LSE plastics, so you can reap the benefits of its shear strength on multiple materials.

Great Tensile and Shear Strength

Our 3M™ Adhesive Transfer Tape 950EK is almost the same as our 3M™ Adhesive Transfer Tape 950. The unique characteristic that differentiates the two tapes? The lining. 3M™ Adhesive Transfer Tape 950EK features an Extensible Polycoated Kraft liner for improved tensile strength and greater tear resistance.

We designed 3M™ Adhesive Transfer Tape 950EK with a high-strength acrylic adhesive, because it offers good UV and chemical resistance, meaning the tape continues to perform despite environmental stresses from the workplace. The acrylic adhesive offers great shear strength too, and that makes Tape 950EK a match for industrial joining applications. Its’ internal strength builds over time, so as the substrates’ surfaces slide over each other, the tape does not yield. Finally, the high tack properties of Tape 950EK mean your tape sticks and sticks quick — minimizing the time it takes to get the job done.

Recommended Applications

- Splicing of film, foils, fabrics

- Laminating adhesive for foams, photos, fabrics, metal or plastic nameplates

- General purpose holding and mounting applications

What are Adhesive Transfer Tapes?

Adhesive transfer tapes are rolls of pressure sensitive adhesive pre-applied to a special release liner. For application, the tape is simply pressed, adhesive side down, to a surface and the liner is peeled off. A variety of adhesive properties and liners are available to meet requirements for applications such as nameplate attachment to high and low surface energy plastics, appliance graphic overlays that perform in high temperatures, foam gasketing, web splicing, signs, posters, banners, point-of-purchase displays, and more.

Bringing Better Ideas to the Surface through Science and Innovation

In our 3M Industrial Adhesives and Tapes Division, we apply the science of adhesion to deliver innovative solutions that improve the design and manufacturing processes of companies around the world. In the end, our technologies help customers like you deliver competitive products to the market faster and more efficiently.

Additional information

| Adhesive Type | Acrylic |

|---|---|

| Indoor/Outdoor | Indoor/Outdoor |

| Industries | Signage, Specialty Vehicle, Print, Transportation, Military & Government, Automotive, General Industrial, Food and Beverage, Converter Solutions, Craft, Point of Purchase, Appliance, Aerospace, Construction, Electronics, Paper, Packaging |

| Maximum Operating Temperature (Celsius) | 121 ℃ |

| Maximum Operating Temperature (Fahrenheit) | 250 ℉ |

| Minimum Operating Temperature (Celsius) | -40 ℃ |

| Minimum Operating Temperature (Fahrenheit) | -40 ℉ |

| Primary Liner | 78# Extensible Polycoated Kraft Paper |

| Primary Liner Color | White |

| Primary Liner Thickness (Imperial) | 5.8 mil, 6 none |

| Primary Liner Thickness (Metric) | 0.15 mm |

| Total Tape Thickness without Liner (Imperial) | 5 mil |

| Total Tape Thickness without Liner (Metric) | 0.127 mm |

| Units per Case | 1.0 Roll,18.0 Roll,36.0 Roll,15.0 Roll |

| Overall Length (Imperial) | 60 yd, 120 yd, 180 yd |

| Overall Length (Metric) | 54.86 m, 110 m, 164.59 m |

| Overall Width (Imperial) | 1 in, 47.25 in, 0.5 in, 0.25 in, 0.12 in |

| Overall Width (Metric) | 25.4 mm, 1,200 mm, 12.7 mm, 6.35 mm, 3.048 mm |